PUSH THE BOUNDARIES OF INTELLIGENCE

Transform your warehousing and distribution with automated garments on hanger (GOH) solutions that maximize time, resources, and customer satisfaction.

PUSH THE BOUNDARIES OF SPEED

Transform your warehousing and distribution with automated garments on hanger (GOH) solutions that maximize time, resources, and customer satisfaction.

PUSH THE BOUNDARIES OF SPACE

Transform your warehousing and distribution with automated garments on hanger (GOH) solutions that maximize time, resources, and customer satisfaction.

Finally, a Solution to Automate Your Garments on Hanger (GOH)

Never before has automation for GOH existed – until now! Engineered specifically for GOH and customized to your needs, our automated solutions allow you to reimagine your warehouse and turn it into a competitive advantage.

Maximize Space

Overcome Labor Challenges

Improve Accuracy

Increase Throughput

Reimagine Your Warehouse With High-Quality Products and Systems

With innovative products like the Carousel Pick Module and the forthcoming GOH Hive™, plus a line of high-performance semi-automated and static systems, we’re able to cover your current and future needs – from distribution and sorting to storing and transporting.

GOH Hive™

GOH Hive™

Handle garments with precision, speed, and accuracy using the first fully automated single-pick storage and retrieval system for GOH.

Carousel Pick Module

Carousel Pick Module

Leverage an automated system to maximize vertical warehouse space and store millions of garments on single-tier, double-tier, or triple-tier carousels.

Automatic Garment Sorter

Automatic Garment Sorter

Sort through garments quickly so that you can process and ship orders with greater speed and accuracy.

V-Rail – Garment Monorail Systems

V-Rail – Garment Monorail Systems

Optimize space and increase inventory storage with a semi-automatic solution that can be customized to suit your unique business needs.

Garment Conveyors

Garment Conveyors

Maximize your space and boost warehouse productivity with a top-of-the-line garment conveyor.

Retail Stockroom Conveyors

Retail Stockroom Conveyors

Make use of available ceiling space to store thousands of garments at a higher level, reserving valuable floor space for shoes or smaller items.

Customized Integrations to Fit the Parameters of Your Business

Easily connect your warehouse planning software to our intelligent systems via customized integrations. Unearth valuable data and insights needed to thrive in today’s marketplace by leveraging the latest technologies.

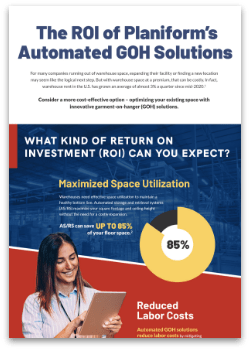

See How Much Space – and Money – You Could Save

Maximize your current warehouse space. Discover the return on investment (ROI) an automated GOH solution can deliver.

Moving These Industries Forward

Dedicated North American and European Support

Local Presence

With offices in Montreal, Canada and Paris and Lyon, France, we offer local support across North America, Europe, and the U.K.

Multilingual Expertise

A multilingual team that speaks six languages, we’re able to clearly communicate and respond to your specific needs.

Access to Parts

Warehouses in Montreal and near Paris offer quick access to critical parts to help keep your system running smoothly.

International Installation

We can install systems across the U.S., Canada, and Mexico as well as locations in Europe and the U.K.

The World Leader in Garment-Handling Innovation

Planiform has delivered innovative GOH solutions to some of the world’s biggest brands for 50-plus years. Unlike much larger companies, we’ve remained nimble, so we are highly responsive and turn projects around quicker.

Work with automation, mechanical, and electrical engineers who are committed to solving problems and staying on the cutting edge. Our team has one goal in mind – to create game-changing products that will revolutionize the automated GOH industry.

“We have had great success with Planiform over the past few years having utilized their products and engineering to build out three important distribution centers. Every project was accompanied by knowledgeable and helpful support. I would definitely recommend Planiform and its talented team for any upcoming project that you may have.”

– John Voris, Former COO, thredUP