Optimize space, increase inventory storage, and reduce manual labor with Planiform’s cost-efficient V-Rail – Garment Monorail Systems.

Increase Efficiency

Move high volumes of garments efficiently with little or no automation required.

Maximize Space

Store trolleys side by side to maximize storage capacity and space in your warehouse.

Save Time and Effort

Get a garment storage and retrieval system that increases the speed and accuracy of order picking.

Stop Wasting Your Valuable Warehouse Space![]()

Planiform garment rails are the most efficient manual method for storing and retrieving large volumes of garments on hangers (GOH). The non-motorized system is cost-effective, is easy to install, and requires low maintenance to deliver an impressive return on investment (ROI).

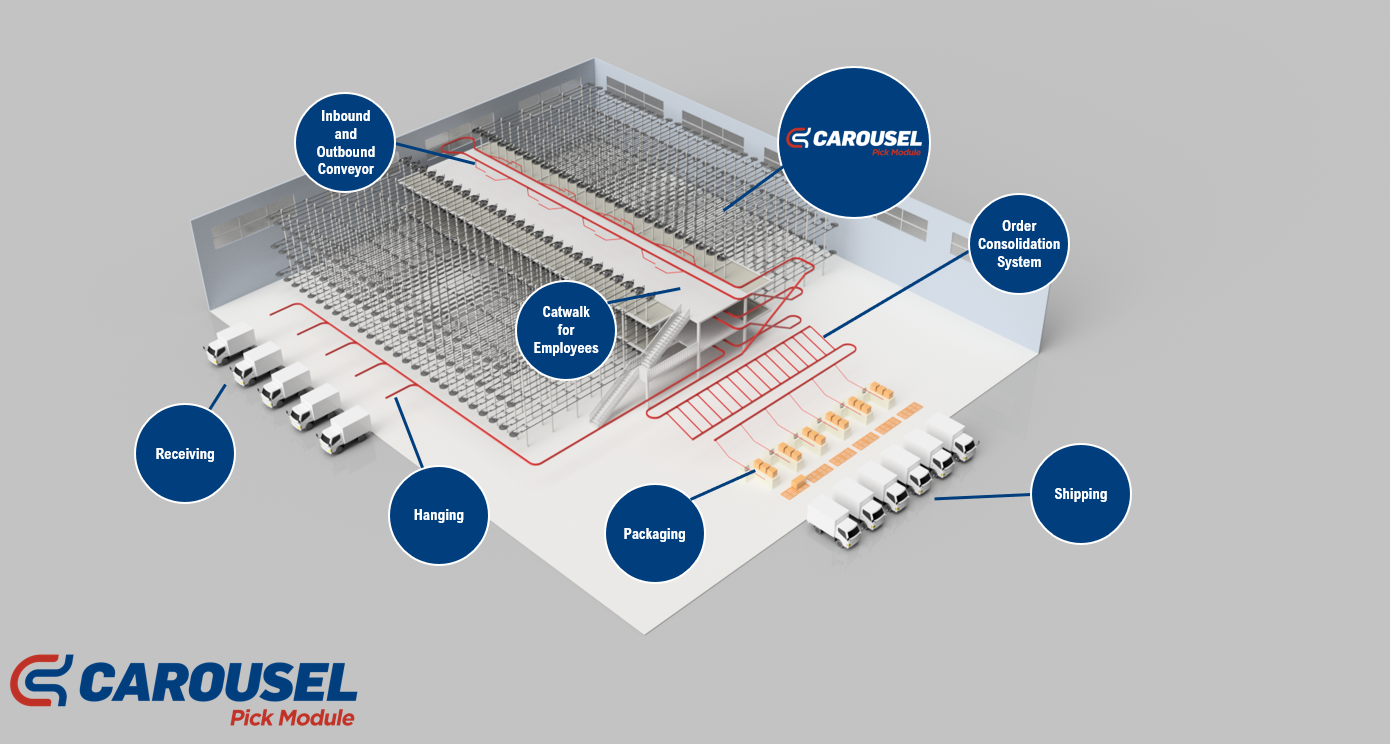

Garments are stored on trolleys that travel on V-Rail lines. The lines can be suspended from the ceiling to free up costly warehouse space. When installed at ceiling level, motorized booster conveyors are used to move the trolleys from ceiling to floor. Multiple levels of V-Rail lines can increase storage capacity, without taking up more warehouse space.

As industry experts in GOH systems, Planiform manufactures and distributes innovative GOH handling systems around the world. We’ll develop GOH solutions to boost your productivity and optimize workflow.

How It Works

Hanging and Storage

Garments are stored on trolleys that roll on V-Rail trackers that can be suspended from the ceiling or a self-standing structure.

Linked Trolleys

Trolleys can be linked together to create trains that make moving garments easy and highly efficient.

Floor-to-Floor Conveyors

The V-Rail system can be installed on multiple levels using motorized booster conveyors that optimize space.

Gain a Competitive Advantage With V-Rail

Gain a Competitive Advantage With V-Rail

Planiform’s V-Rail is a smart solution for storing and sorting many garments while significantly reducing manual labor.

Free Up Valuable Floor Space

Save up to 50% space compared to traditional racking.

Boost Productivity

Easily move high volumes of garments with minimal operator intervention.

Generate a Quick ROI

Benefit from a non-motorized system with a tremendous lifespan.

Protect Garments

Leverage plastic wheels to reduce dust and keep garments in pristine condition.

Improve Ergonomics

Reduce lifting hazards associated with static racking.

Eliminate Aisles

Enjoy high-density storage capacity as no aisles are needed.

Download the whitepaper: The most efficient, organized way to store and retrieve GOH and accessories.

V-Rail System Sales Team

Sales Team

Our qualified sales team is ready to answer your questions. Together, we’ll find the right solution for your business.